Ship Bulk Carrier Crane Kit

A Safe, Simple, and Effective Solution for Ship Cranes

The Viper WRL System has been designed to greatly increase the safety of the operators and improve lubrication effectiveness.

The Viper WRL Bulk Carrier Ship Crane Lubrication Kit has been specifically designed for use in conjunction with the Mini or MID Viper WRL Kit for this application. The kit is supplied as a complete package, with all the components required to get you started. Simply order the kit, the MINI or MID Viper Collar Kit, and then select and order the seals and scrapers to suit the rope size to be lubricated.

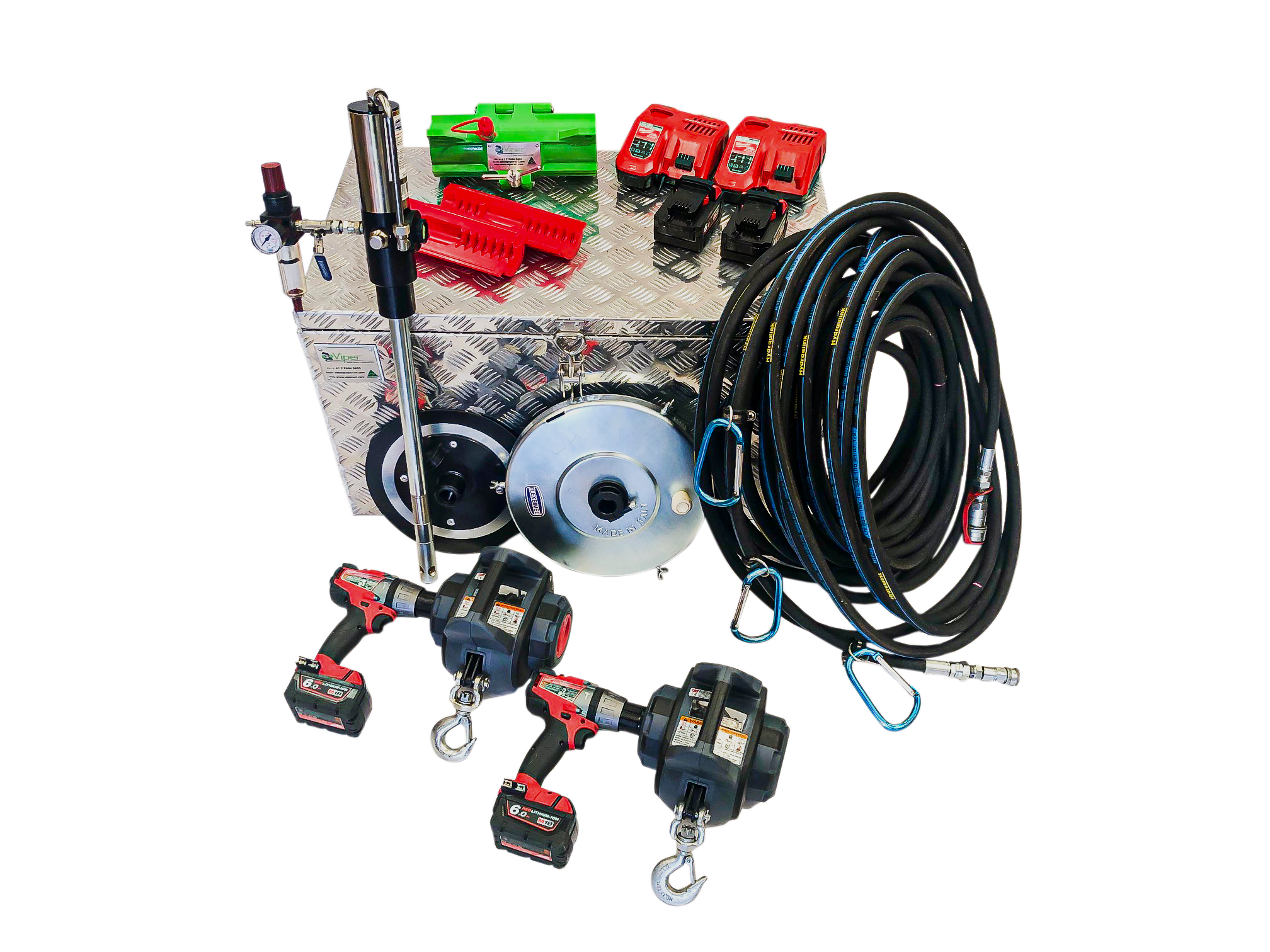

Kit Inclusions

- 2 x Drill winches with Spectra rope

- 2 x Milwaukee Cordless Drills (optional)

- 4 x Lithium-Ion Batteries (optional)

- 2 x Rapid battery charges (optional)

- 1 x 35m 1/2″ Hose with carabiners and quick-connect couplings

- Robust Aluminum storage case

- Operations Manual

- Operations Video

Why Choose the Viper WRL Over Manual Lubrication

Viper WRL

Improved Health, Safety, & Environment

- Viper operators are safely located on the two platforms at

the end of the boom - Viper operators have no direct contact with the lubricant

- The Viper system is cleaner to operate. Excess lubricant

is captured and may be re-used

Reduced Labor Requirements

- The Viper system requires 1 to 2 people to operate and lubrication is completed at +/-7m/min

- The Viper system lubricates the wire strands both internally and externally typically doubling lubrication intervals.

Clean to Operate

- When the Viper WRL is used correctly it generates minimal to no mess

- When using the Viper WRL system all the lubricant stays on the rope with no wastage

- The Viper system requires no rags for lubrication

Enhanced Lubricant Effectiveness

- The Viper WRLs’ unique seal design works the lubricant into the core of the wire rope, which greatly reduces

corrosion and friction and hence greatly extends operational rope life.

Effective Rope Cleaning

- The unique Viper Rope Cleaner removes contamination

from the wire rope prior to lubrication and greatly improves the effectiveness of the lubrication process.

Manual Lubrication

Health Safety & Environmental Concerns

- Safety concern for workers being suspended from the ropes carrying lubricant

- Workers come into close contact with lubricant

- Environmental contamination with excess lube dripping

off ropes

Labour Intensive

- Numerous workers required to lubricate ropes and is very time consuming

- Manual lubrication requires very short re-lubrication intervals due to only coating the outer wires

Extremely Messy

- Mess leads to extra equipment downtime for cleaning

- Lubricant wastage costs money and effects the

environment - Excessive use of rags, gloves, overalls

Ineffective Lubrication

- Typically, only coats the outer wires, lack of penetration to inner sections of rope causes internal corrosion and excessive friction occurs.

Rope Cleaning

- There is no way to manually clean rope effectively at all